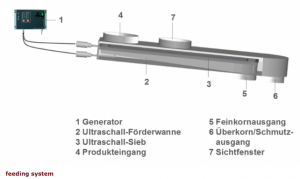

Low frequency feeding of powders is usually carried out by vibrating motors. Sticky and very fine material cannot be fed very well, using this process. Ultrasonic excitation of the tray can improve the feeding effect, and help to distribute the powder more evenly across the tray.

Combining low frequency feeding and high frequency ultrasonic excitation can help to destroy agglomerations.

One possible field of application can be found in particle size analysis, since, due to the more even distribution of the particles on the tray and the destruction of agglomerates, the measuring accuracy can be improved.

Further application possibilities lie in the feeding of powdered pigment from a container to the milling process. Powdered pigment tends to stick to the inner container walls and pipes. Bridge building close to the outlet reduces the flowing speed. Ultrasonic excitation reduces the friction between the powder and the inner wall of the tank, without compacting or unmixing the powder.

The Artech Method can also be applied on feeding without low frequency vibration, just by means of gravity. A tray is being vibrated ultrasonically, and by means of frequency variation the powder will flow down the tray, drawn by gravity.