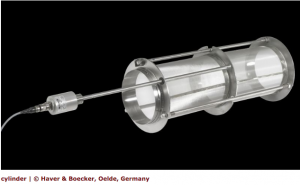

The production of ultrasonic sieves is simplified very much by using the Artech method, because the cloth waveguide does not need to be tuned and the support elements to the frame are not to be fixed in the nodal points.

Coupling the cloth waveguide to the frame, results in a better ultrasound distribution across the sieving mesh, as the ultrasonic energy is conducted to the frame, as well as from the frame to the screen cloth.

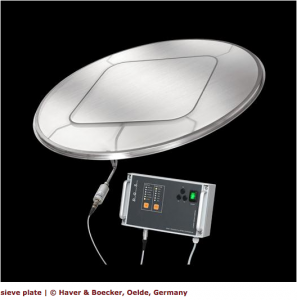

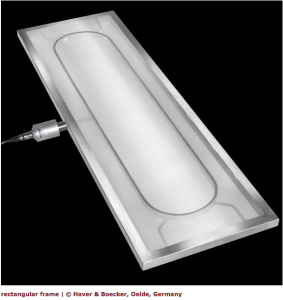

By positioning the converter outside the frame, the following advantages are generated:

- sieving powder deposits do no longer stick to the converter

- simplified and therefore cheaper support mechanics between converter and frame

- handling the sieving deck is simplified due to reduced height, compared to solutions where the converter is mounted directly to the cloth waveguide

- any type of sieving deck can subsequently be equipped with the Artech mechanics

Application-technical advantages:

- highest throughputs because of uniform distribution of the ultrasonic energy across the sieving area

- no or reduced material adhesion to the sieving cloth due to variation of the nodal positions

- reduced dynamical stress owing to variation of nodal point position

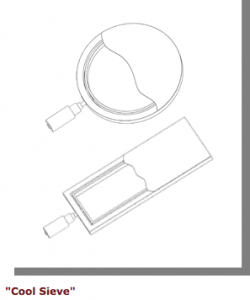

“Cool sieve”:

“Cool sieve”, which is applied for utility patent, integrates the waveguide cloth into the frame.

The advantages:

- easy to clean

- no mechanical parts within the powder flow

- more even distribution of the ultrasound all over the sieving cloth

- prevention / extensive reduction of “hot spots”

“Cool Sieve” | circular & rectangular frame